We ask What if we could change the future by changing building?

We are IMPACTFUL.

- Acknowledging the potential for positive change through design.

We are ETHICAL.

- Design for good and access for all.

We are DEFIANT.

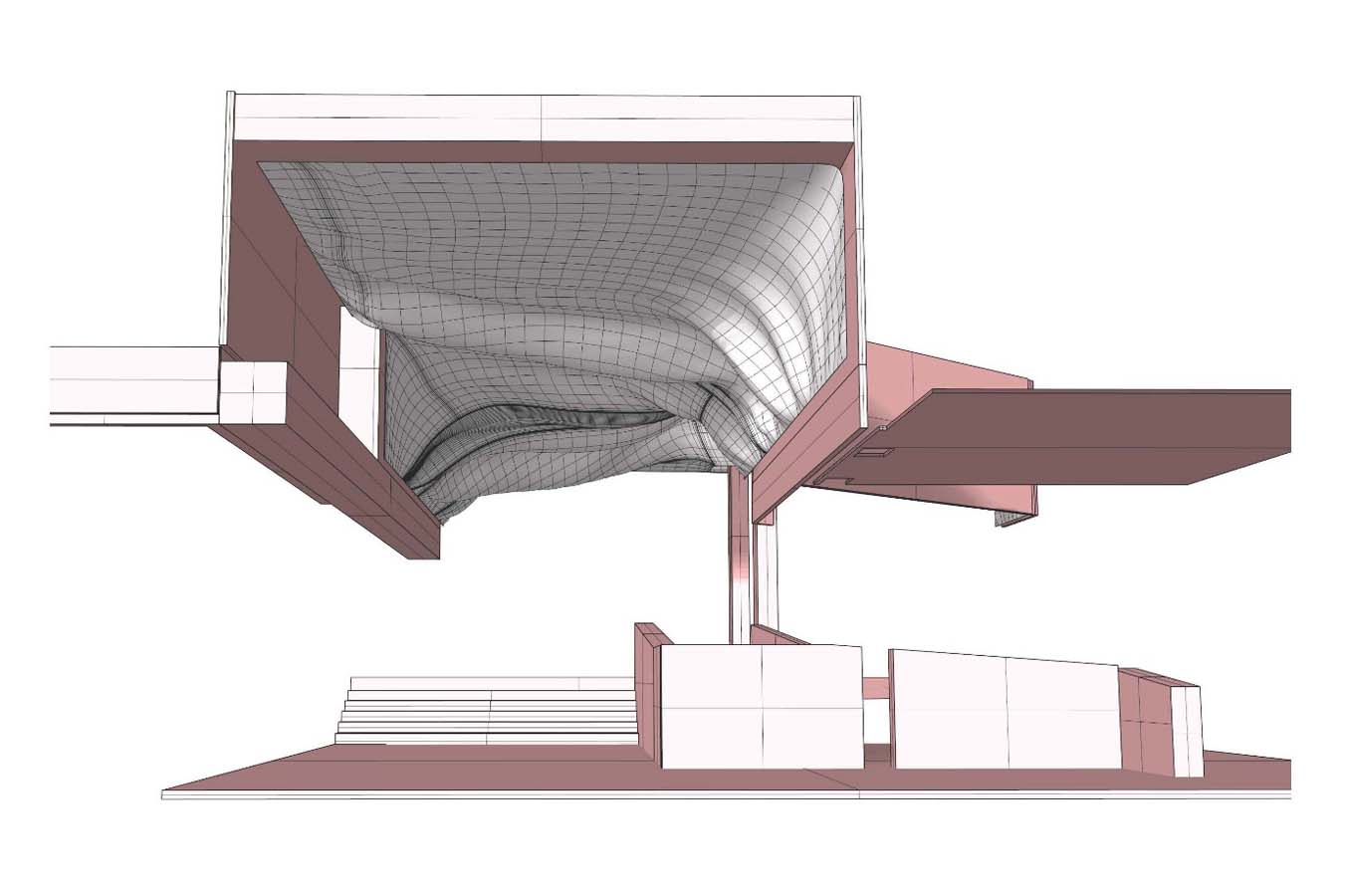

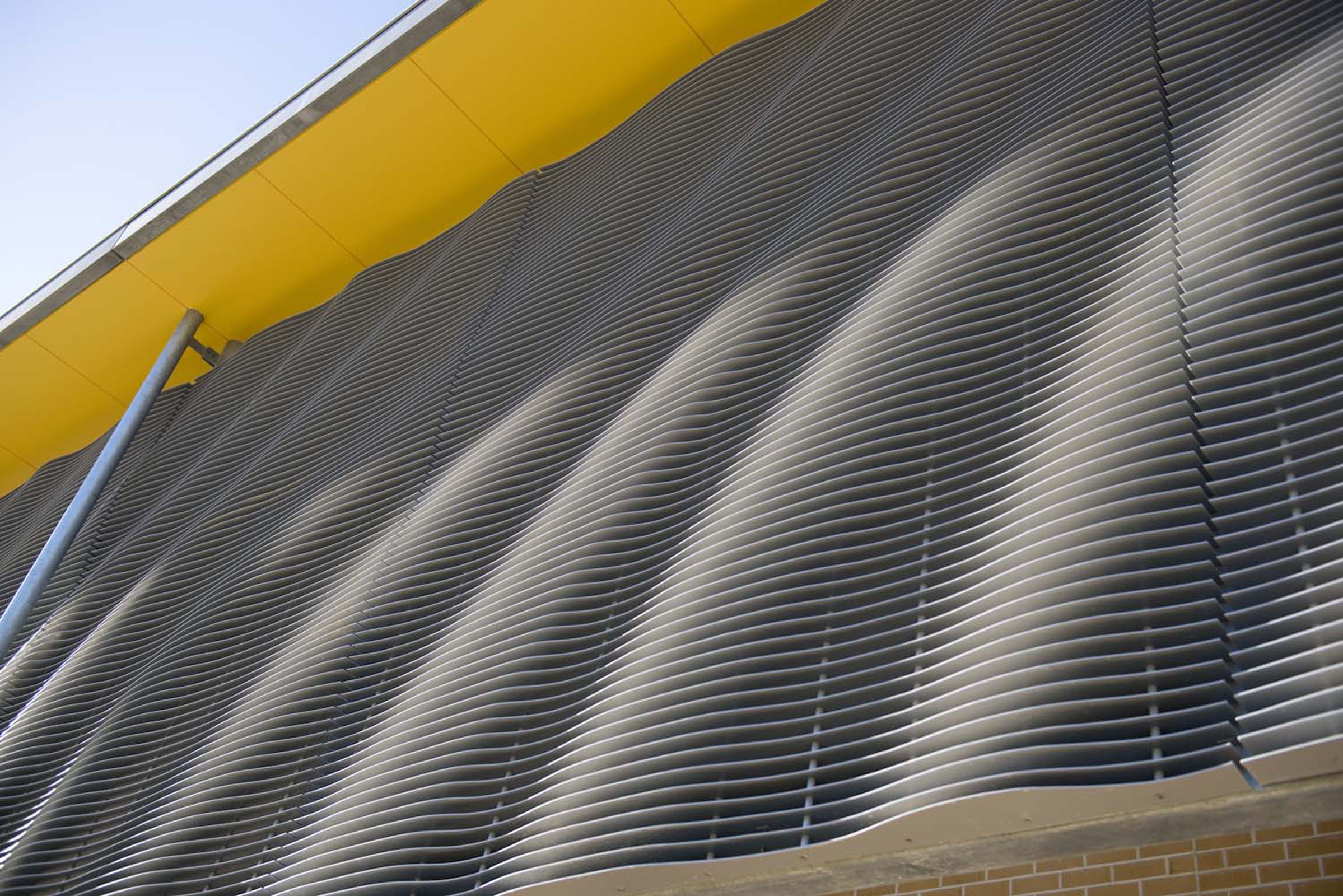

- Challenging the status quo and always searching for a better process and outcome.

Let us help change the way you build

Contact Us

About Your Project

if/LAB is a transdisciplinary design and technology studio based in Perth, Western Australia.

We leverage innovation in design, technology, and manufacturing to enable equitable access to better design for all.