Rhino 3D + Grasshopper Sheet Metal Bending

If/Lab has extended the functionality of Rhino 3D allow for the modelling and unrolling of sheet metal. This bypasses the need for additional solid modelling software to accurately design for the fabrication of sheet metal and allows for seamless integration of design models from file to fabrication reducing time, cost and tolerances.

Rhino 3D is a NURBS based surface modeller offering precise surface representation through mathematically calculations. The software was designed for industrial design, ship building, manufacturing and rapid prototyping and has been adopted in architectural design. Due to its development for complex surface representation it is less suited for the solid modelling required for sheet metal calculations with other software such as Autodesk’s Inventor and Solidworks being better suited to this form of design. However, having to manage information between different programs introduces complexity and the potential for errors and a breakdown in parametric workflows whilst increasing costs in the use of multiple proprietary software’s the training workers.

In exploration of sheet metal workflow solutions with Denmac, if/Lab developed a script that takes mechanical engineering calculations and applies them through Rhino’s visual scripting plugin, Grasshopper. This process extends the capabilities of Rhino and factors in material elasticity for the calculation of bend allowances and deductions to produce accurate unroll patterns for fabrication.

What is bend allowance?

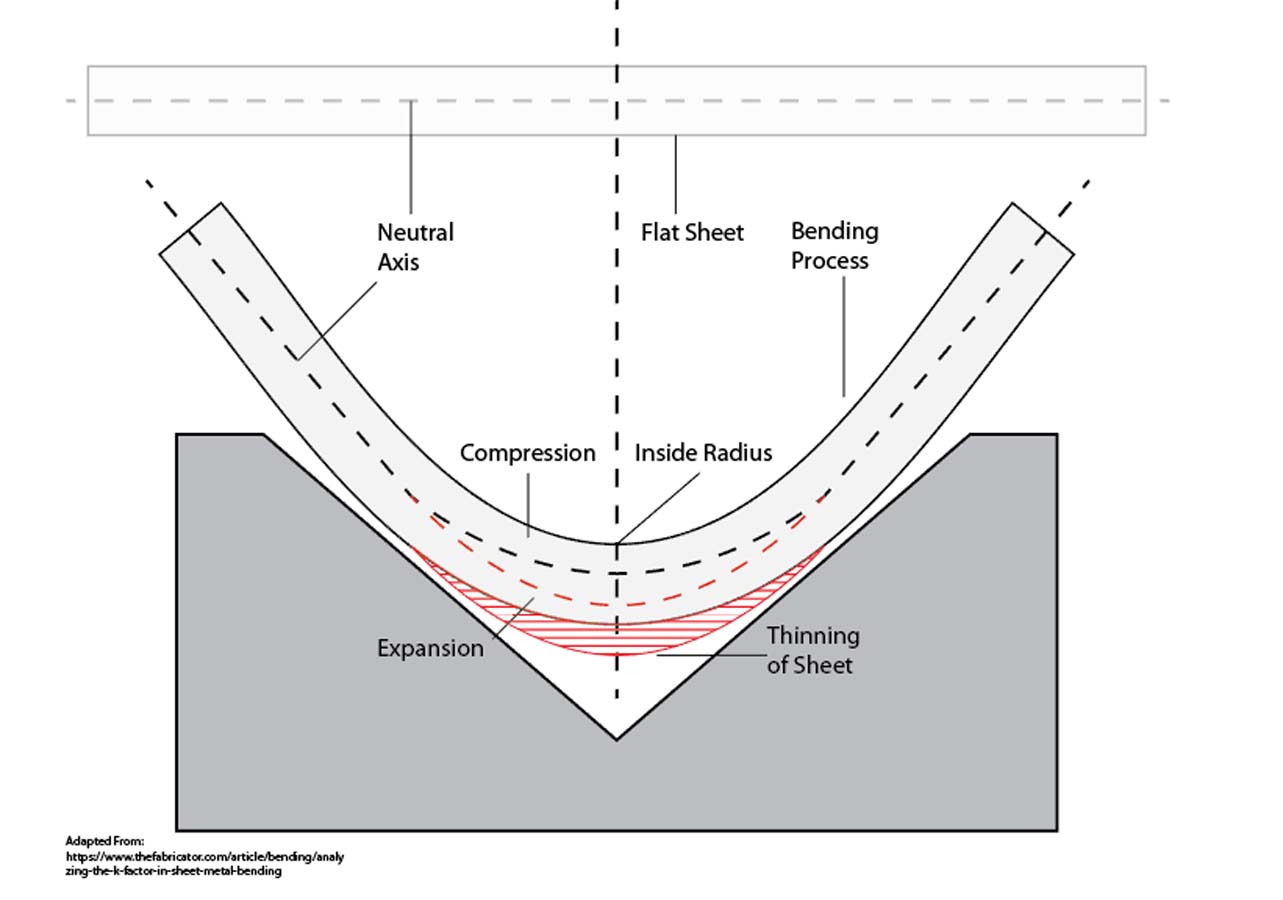

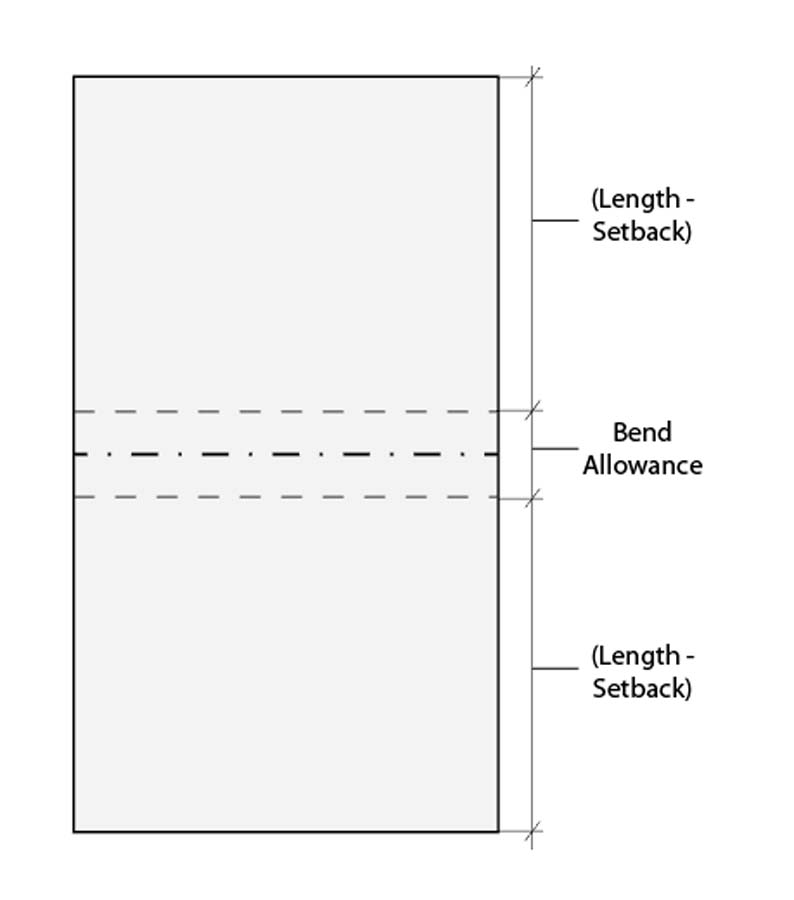

Metal is a ductile material that can be bent along a straight axis to form different shapes. The process occurs by applying pressure that overcomes tensile and compressive material stresses that forces the material to hold a given form. Bending metal does not occur in sharp corners but rather around a radius where the stretching of the material needs to be calculated to accurately to ensure the folded shape is the same as the designed form.

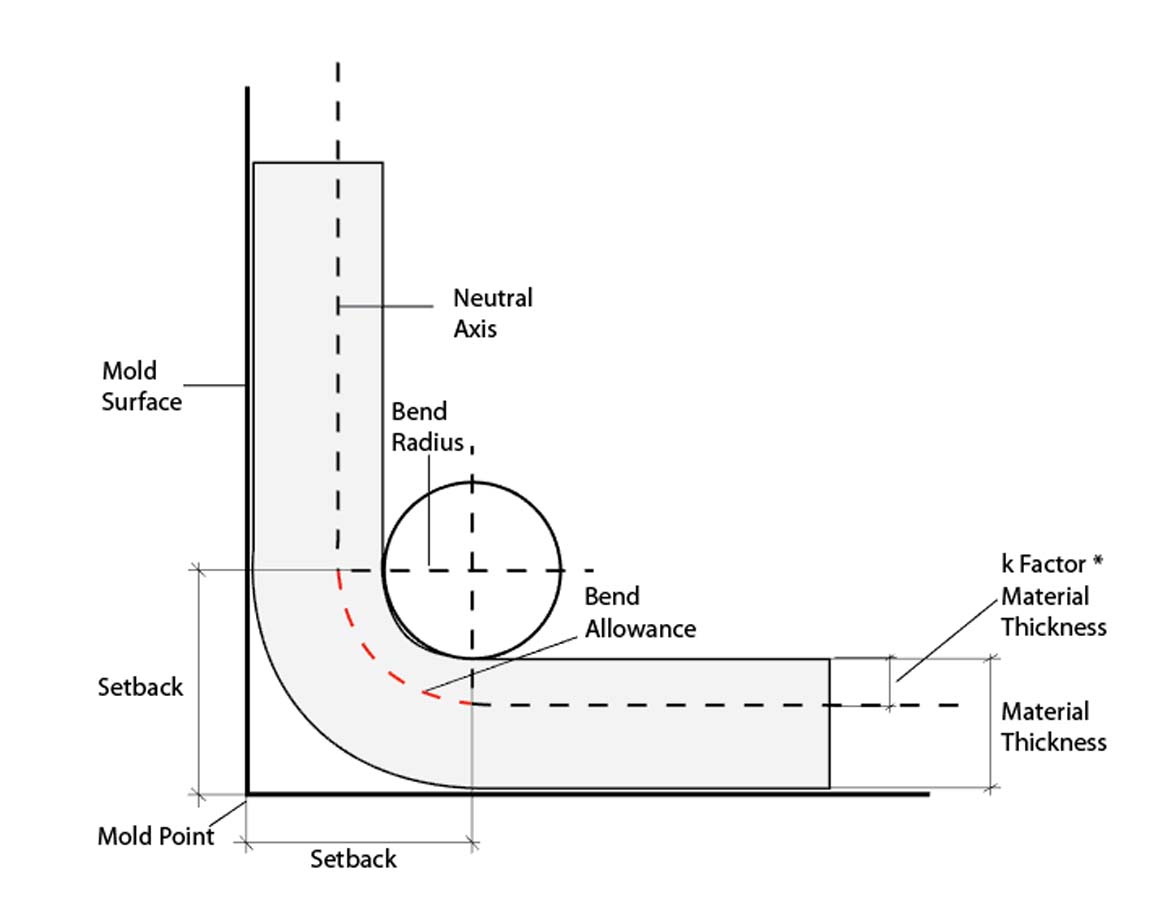

When calculating bends the neutral axis is considered to allow for the elasticity of the material and is the axis in cross section where the material is not in either tension or compression. This varies depending on the specific material and fabrication process and needs to be considered in the unrolled panel increasing the complexity of the bending process.

The k factor is a common process that refers to the calculation that estimates the neutral axis location and allows for a more accurate dimensioning. By creating a script to deal with this complex function, factory standards can be developed, updated and applied with ease.

By using Rhino’s visual scripting plugin Grasshopper, if/Lab was able to run engineering function that extends the capabilities of Rhino to produce accurately modelled and unrolled sheet metal for Denmac’s fabrication requirements without the need for additional software such as Solidworks or Autodesk’s Inventor.

This process works live and parametrically with referenced geometry from Rhino allowing for adaptation to occur in a design and update other downstream dimension, annotation and costing functions giving fast feedback on the effect of design changes.

By holding the information within the same program there is no requirement for extra data management or file formats exchange between software simplifying the process and reducing time. Working with these engineering functions can more accurately design for sheet metal components where results can vary dramatically, and simplification of the process can lead to errors that are both time consuming and costly to fix.

Denmac: https://www.denmac.net.au/

Explore More Insights